Monell engineers the future in GHS Robotics

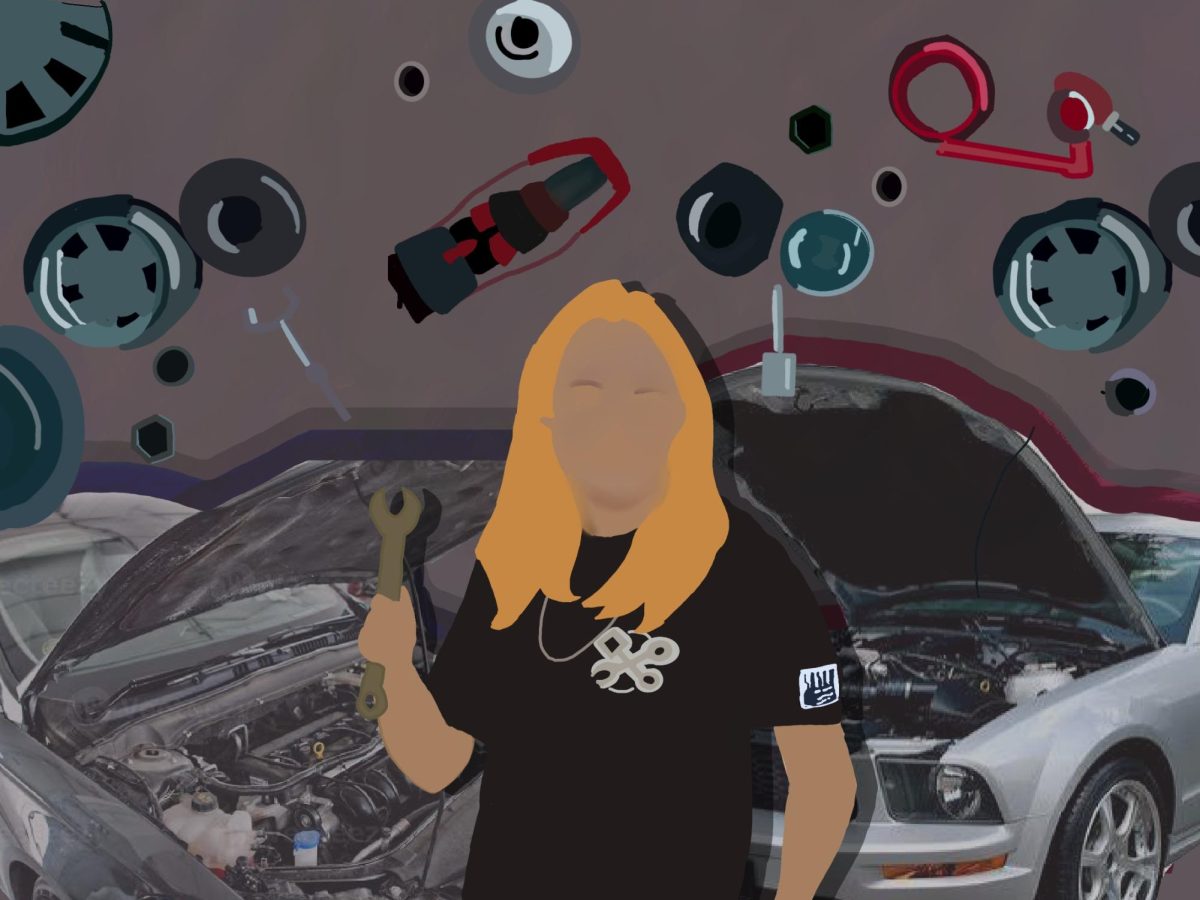

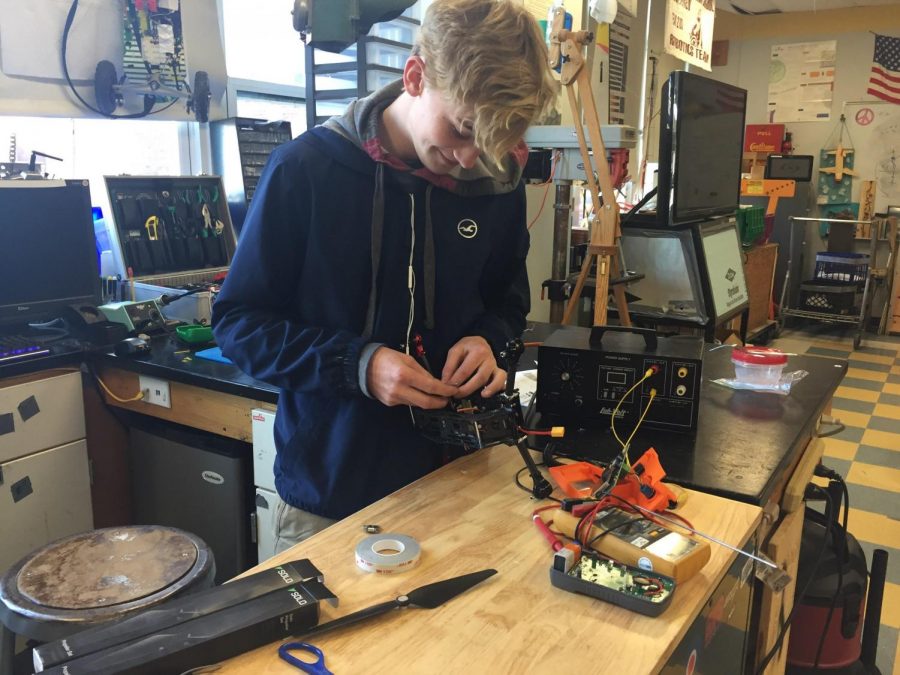

Austin Monell works on his drone project

March 12, 2018

What’s your passion? For GHS junior Austin Monell, it is robotic engineering.

Monell has made a home in Kurt Lichtenwald’s classroom. You can find him working in his space in class, at lunch, and after school.

Monell is currently working on creating a large solar powered airplane drone, but the parts were not only too expensive- they were nonexistent. To solve this, Monell has built a CNC machine to produce the parts he needs.

“It stands for computer numerical control,” explained Monell. “It takes this drill, and the drill can move around on all three axes, and based on what I tell it to do, it cuts it out in the shape I want as opposed to manually, which would take longer and be less accurate.”

The CNC machine will also be a safer option for other students looking to build their parts. It will keep them from having to touch toxic materials, such as the carbon fibre Monell is using. It will also keep them from potentially hurting themselves when carving out tough material.

An obstacle that Monell and others typically face is getting sufficient funding to build their ideas. However, this year Lichtenwald’s class received a $7,000 grant. This was provided by former students of the class who donated their money to the Gloucester Education Fund (GEF).

“Austin, being the CFO (Chief Financial Officer), gets to decide where the money is allocated to,” said Lichtenwald. “He and the next generation of students dictate the direction we take the curriculum.”

However, money comes and goes quickly in an engineering class.

“We’ve already spent it all,” said Monell. “All $7,000. Right now, I’m using it to make airfoils for a solar plane. It helps support the structure of the wind so it can hold the different electronics on the plane. It also holds the solar cells on the plane.”

To draw attention to the project, Monell and Lichtenwald shot and posted a YouTube video of the design process of the CNC machine. It features him designing the parts as a 3D model on the computer, and then assembling the machine. Everything is handmade by Monell.

For Monell, this video was about promoting the class to other GHS students and those out there willing to donate. For Lichtenwald, this was a way to demonstrate Monell’s growth to him and other students.

“It is important for students to prove the mastery of knowledge and pass that on for future generations by creating a video that goes hand in hand with project development,” said Lichtenwald.

This CNC machine and plane he is working on are not the only projects Monell has made.

Another one of his completed projects includes a giant plane that can fly at high altitudes and long distances- with a camera attached to it- and is steered by a remote control. Monell also makes racing drones, which are made of carbon fiber made on the CNC machine.

Monell has also previously created a 3D printer. It is currently being used to make petri dish mounts for Gloucester’s own Ocean Alliance.

Monell has also recently made an acoustic levitation machine, which uses sound waves to levitate small objects.

Interested in doing the things Monell does? Your first step is taking the Robotics Engineering class with Lichtenwald. The class is unique among the sciences, because of Lichtenwald teaching style.

“The kids can generate what projects they’re interested in,” said Lichtenwald. “And we sneak in the math, science, and programming as they’re working on the project.”

Lichtenwald is looking for students who will make their education and careers their own in the classroom.

“Most kids don’t understand until they go onto college what a special place GHS is,” said Lichtenwald. “Especially the engineering program. The level of knowledge you’re obtaining here sets you far above your peers when you go to college.”

As for Monell, he plans to work as a teaching assistant (TA) in Lichtenwald’s intro to engineering class. He wants to attend college for aerospace and robotics engineering. For future projects, he is working fast to complete as many as possible.

“I don’t know if there is time, but I am going to try to build the world’s fastest drone,” explained Monell. “Or build a drone swarm, a collection of drones synchronized together using image processing, which is when a camera recognizes objects and sends feedback to a computer.”